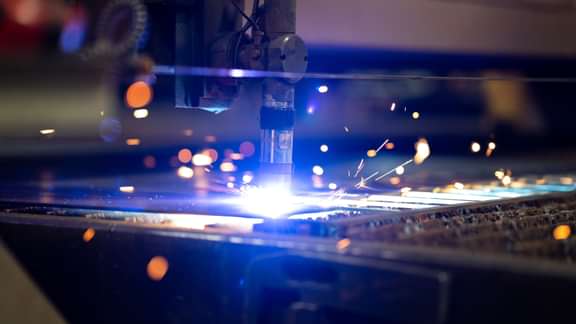

Behlen Custom Fabrication offers plasma and laser cutting services, providing your business with customized solutions according to specific project requirements. We operate fiber and CO₂ laser cutters ranging from 2,600–6,000 Watts and high-definition plasma cutters that handle materials up to 1" x 25'.

Plasma and laser cutters are both popular tools used in metal fabrication and cutting processes, but they operate on different principles and have distinct characteristics.

Here's an explanation of the differences between plasma and laser cutters:

Working Principle

- Plasma Cutter: Plasma cutting involves using a high-velocity jet of ionized gas (plasma) to melt and sever metal. The process begins by creating an electrical arc between the electrode in the torch and the workpiece. This arc ionizes the gas (usually compressed air or inert gas), turning it into plasma. The plasma, at extremely high temperatures, cuts through the metal as it flows out of the torch nozzle.

- Laser Cutter: Laser cutting utilizes a high-powered laser beam to melt, burn, or vaporize material along a predetermined path. The laser beam is generated by exciting a lasing medium, such as CO₂ or fiber, which emits a concentrated beam of coherent light. The focused laser beam interacts with the material, heating it rapidly and causing it to melt or vaporize, resulting in a precise cut.

Cutting Speed and Thickness

- Plasma Cutter: Plasma cutting is generally faster than laser cutting when it comes to thicker materials. Plasma cutters excel at cutting through thick metal plates, typically ranging from 1/8 inch to several inches thick, at high speeds.

- Laser Cutter: Laser cutting is often faster than plasma cutting for thinner materials and intricate designs. Laser cutters can achieve high cutting speeds and precision, especially for materials less than 1 inch thick.

Cut Quality

- Plasma Cutter: Plasma cutting can produce a rougher cut edge compared to laser cutting, with some dross (residue) and heat-affected zone (HAZ) along the cut. However, advancements in plasma cutting technology have improved cut quality significantly, reducing dross and HAZ.

- Laser Cutter: Laser cutting typically yields smoother and cleaner cut edges with minimal dross and HAZ. This makes laser cutting ideal for applications requiring high precision and aesthetic quality, such as architectural components and decorative pieces.

Material Compatibility

- Plasma Cutter: Plasma cutting is versatile and suitable for cutting various conductive materials, including mild steel, stainless steel, aluminum, copper, and brass.

- Laser Cutter: Laser cutting is highly versatile and can cut a wide range of materials, including metals, plastics, wood, fabrics, and composites. However, it may not be as effective for highly reflective materials like copper and brass.

Operating Cost

- Plasma Cutter: Plasma cutting systems generally have lower initial equipment costs compared to laser cutters. Additionally, plasma cutters may have lower operating costs for cutting thicker materials due to lower energy consumption.

- Laser Cutter: Laser cutting systems typically have higher initial equipment costs but may offer lower operating costs for cutting thinner materials due to higher cutting speeds and efficiency.

In summary, plasma cutters are well-suited for cutting thick metal plates at high speeds, while laser cutters excel at precision cutting of thinner materials with smoother edges. The choice between plasma and laser cutting depends on factors such as material thickness, cut quality requirements, speed, and budget considerations.